Instead, there are electronic devices consisting of transistors and resistors. From there the name of the electronic ignition system was taken.

But, the electronic ignition system has some type.

Today we will discuss two types of electronic ignition systems that are widely diplomatic in vehicles.

1. Transistor ignition system

As the name implies, transistorized ignition system is an ignition system that uses transistors to change the breaker point.

We will repeat a little about the breaker point, the breaker point is the mechanism for disconnecting the primary circuit of the ignition coil. Termination of the primary circuit is intended to trigger the induction of the ignition coil.

The breaker point works like a normal switch which if the plate is stretched the primary circuit will be broken and when the plate is tight the primary circuit is re-connected.

The weakness of the breaker point is the wear on the plate. This is because the plate will always be rubbing against the cam. So that in a certain time it will change the angle and reduce the ignition system performance.

Then what about the transistor?

Transistors are electronic components that has a function like electronic switches.

We know that transistors have three legs, a collector, an emitter and a base. The collector is the input of the primary circuit, the emitter is the output of the transistor going to ground while the base is the transistor controller.

The transistor is working if there is current at the base, it will connect the collector and emitter so in this point, the primary voltage will be continue to the ground. While if the current at the base is stopped, then the emitter and the collector will be disconected.

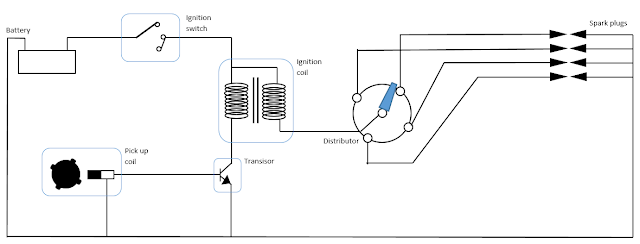

You can see the transistorized ignition system diagram below

Additional components of the transistorized ignition system;

Pick up coil, this component serves to detect ignition timming. It works by flowing an electric wave where in that wave there is a voltage drop, the voltage drop indicates ignition timming.

The advantages of a transistorized system

- Do not use breaker points so there is no need to adjust the breaker points.

- Ignition timing is more accurate

- Have a simpler scheme

However, transistorized ignition systems still use distributors to distribute high-voltage electricity from the secondary ignition coil to each spark plugs. So it still has mechanical components, therefore it is also called the semi electronic ignition system.

2. Distributorless ignition system

Distributorless ignition system is an ignition system that does not use a distributor. Distributors are required to distribute the high voltage from the secondary output ignition coil circuit.

This component works mechanically, so there is a usage limit where when the limit is reached then the connection to the distributor will weaken so that the spark plug fire weakens.

But on the DLI system, we did not find a distributor. That's because the DLI system already has a full electronic computerized ignition system.

That means, in addition to being full electronic the DLI system has also implemented computer-based calculations as a controller.

In a simple DLI system scheme you can see in the diagram below;

You can see for yourself there are many circuits on the DLI system. It has three main parts, they are ECU, Ignition coil module, and ignition coil pack

ECU is a microcontroller device that functions to regulate the performance of the ignition coil, especially when the ignition coil is active. In doing its job, the ECU is assisted by many sensors such as the crankshaft position sensor to detect ignition timing and camshaft position sensors to detect ignition timming on cylinder 1.

The sensor will send data to the ECU, then the ECU processes the data and the results are sent to the output device, the Ignition coil module.

Ignition coil module actually consists of several transistors, the function is the same as a transistor ignition system that is as an electronic switch. However, this has more numbers. The number of transistors in the ignition coil module matches the number of coil.

Ignition coil pack, is a feature of the DLI system. Coil pack consists of several mini coil. Generally there are two coil (dual coil pack) and four coil (single coil pack).

For dual coil packs, a coil is used for two spark plugs. This causes two spark plugs ignite at the same time, while in a single coil pack one coil is used for one spark plug so that all spark plugs will ignite alternately.

Advantages of DLI systems

- No maintenance at all because it is full electronic

- Transfer voltage from the coil is more effective

- Ignition timing is more accurate

While the disadvantages, DLI systems have quite complicated circuits. For the technicians who hasn't the knowledge will difficult to solve the problem on DLI system. Usually, the error can be detected using a a scanner so that it is more inconvenient and expensive when damage occurs. Sumber https://www.autoexpose.org/